|

XI'AN ZZ TOP OIL TOOLS CO.,LTD

|

DST 5" Round Mandrel slip joint

| Price: | 500.0 USD |

| Payment Terms: | T/T,L/C,D/A |

| Special Groups: |

DST Tools (146)

DST Slip Joint (2) DST round mandrel slip joint (3) drill stem testing (124) Open Hole DST (53) |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

5" Round mandrel slip joints is made of Inconel, and worked for Full H2S drill stem testing service, the DST tools are on shelf for quick delivery.

5" Round Mandrel slip joint for Full H2S drill stem testing

The round mandrel slip joint, like other slip joints, accepts the movement associated with ocean heave or

temperature change without allowing the movement to disturb the placement of downhole tools.

The round mandrel slip joint has the following characteristics:

• Top of the mandrel slip joint has 4 3/4-in. (120.65-mm) drill collar profile for easy handling with the rig elevators and slips

• Maintains its full tensile rating when collapsed and locked

• Can be locked in the closed position for handling, reducing the risk of damage to the lifting/sealing mandrel

• Internally pressure and volume balanced

• String can be picked up with the slip joint locked; the slip joint can then be unlocked before it is run into the hole

• Provides free travel in the string to reciprocate tools without unseating the packer.A slip joint operates by balancing its volume. As the slip joint stretches and increases its internal volume, a differential piston within the slip joint allows the same volume of fluid into the pipe. The net result is no change ininternal volume.

Each slip joint has 5 ft (1.52 m) of travel but can be combined with other slip joints to provide additional travel.When multiple slip joints are run, they are normally connected to one another rather than located throughout the pipe string. The number of slip joints required depends on ocean heave and the amount of expected contractionand expansion.

Features

• Provides a variable-length joint to allow the pipe to expand and contract during testing or stimulation

• Keeps vertical movement of the drilling vessel from disturbing tool placement

• Helps space out the testing string when the subsea tree is landed

• Provides a constant weight on the packer during testing or stimulation

Specification

Nominal Tool Size in. | OD in. | ID in. | Thread Connections | Temperature/F | Stroke Length /in. | Tensile Rating/lb | Working Pressure/ psi |

37/8 | 3.90 | 1.80 | 2 7/8 CAS | 450 | 60.00 | 416,000 | 15,000 |

5.00 | 5.03 | 2.28 | 3 7/8 CAS | 450 | 60.00 | 416,000 | 15,000 |

Facilities

Customer facility tour

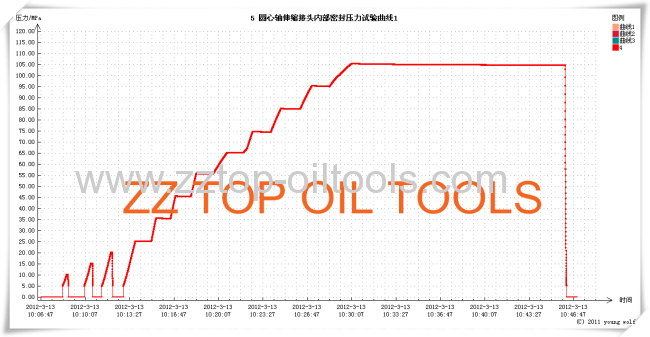

Pressure test chart for round mandrel slip joint

With the skilled and experienced engineers, we can design the drill stem testing tools as per customer's well condition. Moreover, we supply the training in our factory and operation instruction at the well site. The DST tools are exported to USA, Colombia, India, Pakistan, Iran, Brazil etc. and enjoy the good reputation from the customers.

To shorten the delivery time, we proceeded the DST Tools in stock:

Packer,circualting valve,select tester valve,APR N-valve,OMNI valve,Hydraulic Jar,Tubing string tester

1. Full bore Packer, 7" Casing, working pressure 70Mpa, Working Temperature 400F, Connection: IF, 4set

2. Tester valve, 5", Working pressure 105Mpa, Working temperature 400F, Connection CAS. BXP, 4 sets

3. Hydraulic Jar,5", Working pressure 105Mpa, Working temperature 400F, Connection CAS. BXP, 4sets

4. Rupture disk Circulating valve, 5", Working pressure 105Mpa, Working temperature 400F, Connection CAS. BXP, 4sets

5. Flowhead (surface test tree), 3 1/16", working pressure 70 Mpa. 1set

Should you have any interest or inquiry on the Drill stem testing tools, contact us freely.

.jpg)