|

XI'AN ZZ TOP OIL TOOLS CO.,LTD

|

Cased Hole Drill test testing Multicyle circulating valve OMNI

| Price: | 100.0 USD |

| Payment Terms: | T/T,L/C |

| Special Groups: |

Case hole DST (111)

DST Tools (146) DST Multi-circulating valve (8) DST OMNI valve (6) drill stem testing (124) Open Hole DST (53) |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Drill stem testing tools multicycle circulating OMNI valve is for cased hole full bore type in size 3 7/8" and 5" in owrking pressure 105Mpa,16 rachet

Cased Hole Drill test testing Multicyle circulating valve OMNI

Cased Hole Drill test testing Multicyle circulating valve OMNI

Brief introduction

OMNI circulating valve is a full opening, annulus pressure-operated re-closable circulating valve which can be open and closed many times. The tool is operated by repeatedly cycling the annulus pressure up to a predetermined value and then releasing this pressure.

OMIN Vale is acceptable for the full-opening formation testing in cased hole, oil tube tradition perforation, tube string testing and cycle operation in the conjunction of perforation and full-opening formation testing. It overcomes the shortcomings of some other circulating valve, at a certain position, can use the annulus pressure to operate other tools many times and there is no influence upon the OMNI circulating valve. Because of the ability of opening and closing the well many times, it can carry on acidification and fracturing etc. other well stimulations in the end of the full-opening formation test. Using the valve can make the test program simple and reduce the reconnoitering cost greatly.

OMNI circulating valve has two kinds: 3 7/8″ and 5″. They all can run in subsurface environment which contains acid.

No | Specification | 5" |

1 | OD | 127.5mm |

2 | ID | 57mm |

3 | Length | 6555mm |

4 | Working pressure | 105Mpa |

5 | Ball valve Open Differential pressure | 35Mpa |

6 | Ball valve top and bottom differential pressure | 70Mpa |

7 | Internal Pressure strength | 146Mpa |

8 | External pressure strength | 136Mpa |

9 | Tensile strength | 2034KN |

10 | Torque strength | 31.6KN.m |

11 | Circulating Flow area | 2280mm2 |

12 | Service | H2S,NACE MR0175(>175oF) |

13 | Working temperature | -29℃+204℃ |

14 | Connection thread | 3 7/8″CAS.B×P or 3 1/2″IF.B×P |

Working principle

OMNI circulating valve completes the function by increasing and releasing the annulus pressure .

According to the construction features it can be learned when increasing the annulus pressure, the piston push the hydraulic oil to move to the left, and the hydraulic oil push the check valve assemblies to move to the left until to the upper dead point, then the hydraulic oil pass the passageway and push the floating piston in the nitrogen chamber, thus the pressure is saved in the nitrogen chamber.

When releasing the pressure, because the pressure in nitrogen chamber is above the annulus

pressure ,the nitrogen pressure push the floating piston in the nitrogen chamber and then to hydraulic oil move to the right, the check valve assemblies to move to the right under pushing of hydraulic oil until

to the lower dead point, the hydraulic oil make the nitrogen pressure equal to the annulus pressure.

Nitrogen Charging Table-5" OMIN Circulating Valve

Surface temperature:0oF Pressure Unit: PSI Temperature Unit: oF

HYDROSTATIC PRESSURE | ||||||||||||||||

Mud Temp. | 2000 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 | 9000 | 10000 | 11000 | 12000 | 13000 | 14000 | 15000 | 16000 | 17000 |

50 | 1578 | 2310 | 3011 | 3630 | 4348 | 4985 | 5619 | 6253 | 6885 | 7504 | 8104 | 8710 | 9254 | 9843 | 10403 | 10941 |

75 | 1488 | 2169 | 2820 | 3444 | 4064 | 4654 | 5247 | 5842 | 6418 | 7003 | 7563 | 8141 | 8663 | 9198 | 9739 | 10280 |

100 | 1406 | 2045 | 2652 | 3239 | 3814 | 4373 | 4930 | 5499 | 6024 | 6577 | 7118 | 7651 | 8182 | 8694 | 9206 | 9731 |

125 | 1337 | 1940 | 2511 | 3065 | 3601 | 4133 | 4650 | 5176 | 5679 | 6189 | 6701 | 7206 | 7709 | 8211 | 8693 | 9175 |

150 | 1274 | 1845 | 2385 | 2911 | 3416 | 3918 | 4408 | 4897 | 5380 | 5860 | 6345 | 6830 | 7307 | 7795 | 8269 | 8730 |

175 | 1219 | 1762 | 2275 | 2772 | 3252 | 3723 | 4193 | 4650 | 5108 | 5561 | 6013 | 6473 | 6930 | 7386 | 7849 | 8294 |

200 | 1168 | 1687 | 2175 | 2648 | 3106 | 3552 | 4001 | 4433 | 4870 | 5302 | 5734 | 6165 | 6602 | 7043 | 7477 | 7920 |

225 | 1122 | 1620 | 2086 | 2536 | 2975 | 3401 | 3822 | 4242 | 4654 | 5067 | 5477 | 5881 | 6294 | 6718 | 7136 | 7552 |

250 | 1080 | 1558 | 2005 | 2436 | 2856 | 3264 | 3666 | 4068 | 4458 | 4853 | 5246 | 5630 | 6016 | 6421 | 6825 | 7225 |

275 | 1042 | 1502 | 1931 | 2345 | 2748 | 3140 | 3524 | 3906 | 4285 | 4659 | 5032 | 5401 | 5770 | 6150 | 6522 | 6906 |

300 | 1006 | 1450 | 1864 | 2261 | 2649 | 3025 | 3395 | 3760 | 4125 | 4482 | 4840 | 5196 | 5546 | 5907 | 6274 | 6645 |

325 | 683 | 1403 | 1802 | 2185 | 2559 | 2922 | 3277 | 3627 | 3978 | 4323 | 4661 | 4999 | 5338 | 5683 | 6028 | 6384 |

350 | 658 | 1358 | 1744 | 2116 | 2476 | 2827 | 3169 | 3507 | 3841 | 4178 | 4498 | 4826 | 5151 | 5483 | 5816 | 615 |

375 | 636 | 1317 | 1691 | 2051 | 2399 | 2737 | 3070 | 3393 | 3715 | 4038 | 4351 | 4661 | 4973 | 5295 | 5614 | 5933 |

400 | 615 | 1279 | 1642 | 1990 | 2328 | 2653 | 2977 | 3289 | 3600 | 3910 | 4217 | 4511 | 4815 | 5123 | 5432 | 5741 |

425 | 596 | 1243 | 1596 | 1934 | 2262 | 2578 | 2890 | 3194 | 3494 | 3790 | 4089 | 4375 | 4664 | 4961 | 5259 | 5556 |

450 | 578 | 1209 | 1553 | 1881 | 2200 | 2508 | 2810 | 3107 | 3395 | 3684 | 3971 | 4251 | 4526 | 4815 | 5102 | 5390 |

475 | 561 | 1178 | 1512 | 1832 | 2143 | 2441 | 2735 | 3022 | 3318 | 3581 | 3857 | 4133 | 4399 | 4676 | 4954 | 5233 |

500 | 545 | 1148 | 1474 | 1786 | 2089 | 2379 | 2664 | 2944 | 3247 | 3486 | 3754 | 4023 | 4283 | 4548 | 4820 | 5090 |

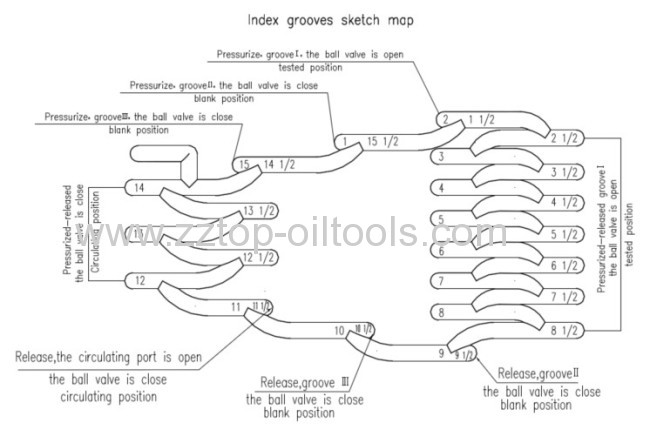

16 rachets Indexing groove drawing.

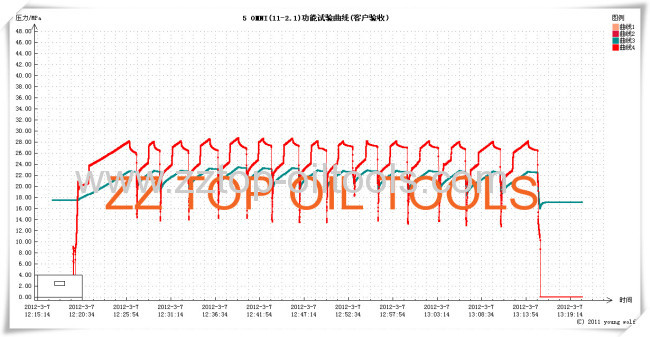

OMNI Function Testing Chart

ZZ TOP OIL TOOLS is the professional manufacturer for the drill stem testing tools and surface testing equipment. All the DST tools are conformed with NACE MR 0175 with traceability,and the DST tools can be worked in H2S & CO2 above 175 F and full H2S, also with the skilled and experienced engineers, we can design the drill stem testing tools as per customer's well condition. Moreover, we supply the training in our factory and operation instruction at the well site. The DST tools are exported to USA, Colombia, India, Pakistan, Iran, Brazil etc. and enjoy the good reputation from the customers.

To shorten the delivery time, we proceeded the DST Tools in stock:

Packer,circualting valve,select tester valve,APR N-valve,OMNI valve,Hydraulic Jar,Tubing string tester

1. Full bore Packer, 7" Casing, working pressure 70Mpa, Working Temperature 400F, Connection: IF, 4set

2. Tester valve, 5", Working pressure 105Mpa, Working temperature 400F, Connection CAS. BXP, 4 sets

3. Hydraulic Jar,5", Working pressure 105Mpa, Working temperature 400F, Connection CAS. BXP, 4sets

4. Rupture disk Circulating valve, 5", Working pressure 105Mpa, Working temperature 400F, Connection CAS. BXP, 4sets

5. Flowhead (surface test tree), 3 1/16", working pressure 70 Mpa. 1set

Should you have any interest or inquiry on the Drill stem testing tools, contact us freely.

.jpg)