|

XI'AN ZZ TOP OIL TOOLS CO.,LTD

|

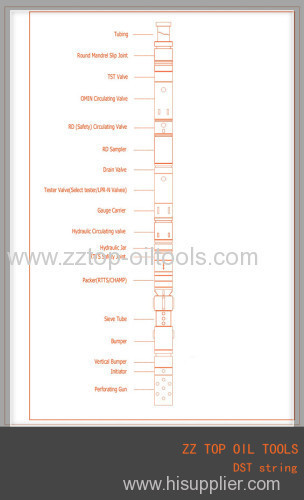

Full bore annular pressure operated drill stem testing tools(DST)

| Price: | 2000.0~20000.0 USD |

| Payment Terms: | T/T,L/C |

| Special Groups: |

DST Tools (146)

drill stem testing (124) |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The Drill stem testing tools(DST) is full bore type with annular pressure operated, high working pressure and working temperature, service NACE MR0175

General Information

Tools features:

1. Full bore type which can be available for slickline/wireline testing.

2. Annular pressure operated.

3. Short time Maintenance.

4. High pressure and high temperature working condition.

5. Suitable for H2S, CO2, HCL, Acid serivce

Tools Working Case:

1. Colombia- Normal working service, Gas sealing thread perfect.

2. Kuwait-High H2S percetage, High temperature

3. Austrilia-Normal Working service

4. Brazil: Offshore working, Super safety valve ncessary

5. Lybia: Normal service.

The DST tools manufactured by ZZ Top is full bore type and annular pressure operated, applicable for 4 1/2" to 20" casing, the tools OD is 3 7/8" and 5", Working pressure upto 105Mpa, working temperature upto 425F.

As per NACE MR0175 standard, the materials ZZ Top used is AISI41XX Alloy steel with hardness in 30HRC in average but also consider the high working pressure to choose high hardness material used in Critical parts i.e. Nitrogen Case, for ball valve, the material is Inconnel 718 which import from USA directly.

And for strict working condition such as high H2S, CO2, Acid and HCL, we also suggest the material Inconnel or other high Nickel alloy steel.

For other redress parts like O rings, rupture discs are also optional from US parker and Fike USA, and as per our test Chinese are also in good performance, those parts can be availably once request.

Regarding DST tools, the maintenance is very important for each well running, replace all O rings after a job is very necessary to keep tools in well condition, ZZ Top also provide DST maintenance training in user site and in factory.

ZZ Top is running under ISO9001:2008, and all tools were certified by SGS in full process, from material to final function testing.

Tools features:

1. Full bore type which can be available for slickline/wireline testing.

2. Annular pressure operated.

3. Short time Maintenance.

4. High pressure and high temperature working condition.

5. Suitable for H2S, CO2, HCL, Acid serivce

Tools Working Case:

1. Colombia- Normal working service, Gas sealing thread perfect.

2. Kuwait-High H2S percetage, High temperature

3. Austrilia-Normal Working service

4. Brazil: Offshore working, Super safety valve ncessary

5. Lybia: Normal service.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Full Bore Ball Valve

Full Bore Valve

Ball Valve Full Bore

Network Testing Tools

Pressure Operated Valve

Drill Tools Kit

More>>

.jpg)