|

XI'AN ZZ TOP OIL TOOLS CO.,LTD

|

DST 3 7/8" Rupture Disk Sampler RD Sampler

| Price: | 500.0~10000.0 USD |

| Payment Terms: | T/T,L/C,D/A |

| Special Groups: |

DST Tools (146)

drill stem testing (124) |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Rupture Disk (RD) SamplerSize:3 7/8"

Standard: NACE MR0175

Service:Full H2S

Usage: Drill stem testing

Type: Full bore sleeve sample

3 7/8" Rupture Disk Sampler RD sampler

The rupture disk sampler is a full-open, full bore sleeve sampler for use on drill stem tests. The sampler is controlled by a rupture disk that is operated by annulus pressure.

Features

• Time-delay feature allows the sample to be trapped after a preset time. Different metering cartridges can be used to vary the closing time.

• Full-open capabilities are retained after the tool has trapped its sample.

• Several samplers can be run on a test to allow sampling at different times.

Operation

The sampler is controlled by a pressure-operated rupture disk and has a sample mandrel with a built-in differential area. To catch a sample, annulus pressure is increased to a predetermined level, the rupture disk in the sampler breaks, and the mandrel traps the sample.

When the rupture disk breaks, the differential area of the sample mandrel is exposed to an air chamber on one side and hydrostatic pressure and applied annulus pressure on the other. This condition results in the sample mandrel moving up and trapping the sample. When the sample mandrel reaches the top of its stroke, it is locked in place by a set of locking dogs.

The 1,200-cc sample chamber allows a sufficient sample for two 500-cc nonmonophasic (bulk) samples.

Specifications:

Specifications:

| Product model: | Rupture Disk (RD) Sampler |

| Size: | 3 7/8" |

| Standard: | API |

| Material | AISI 41xx, Inconnel |

| Type: | Full-open, full bore Rupture Disk sample |

| Usage: | Drill stem testing |

| Standard: | API |

| Service: | H2S above 175oF; Full H2S service |

| Working condition: | High pressure high temperature |

Below are spec

Nominal Toot Size in. | OD in. | ID in. | Thread Connections | Length in. | Tensile Rating/ lb | Working Pressure/psi | Sample Volume cc |

3 7/8 | 3 .8 | 1.80 | 2 7/8 CAS | 131.00 | 202.000 | 15,000 | 1,200 |

5.00 | 5.0 | 2.28 | 3 7/8 CAS | 82.00 | 342 000 | 15,000 | 1,200 |

Test preparation

Testing equipment

Pressure Testing Equipment

Testing equipment for Rupture Disk

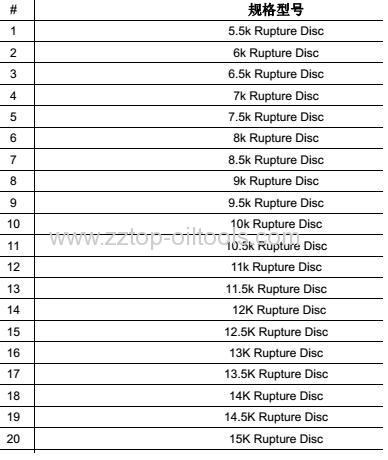

Rupture Disk Specif.

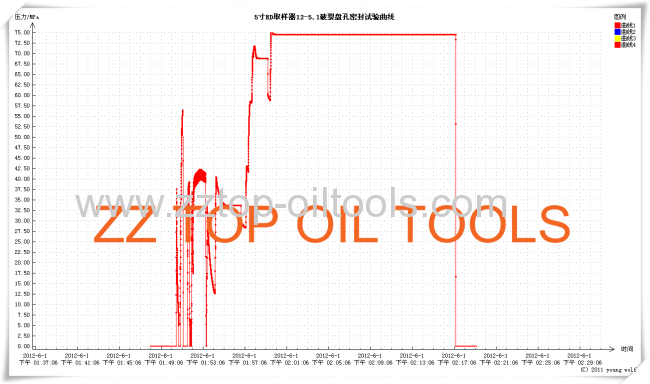

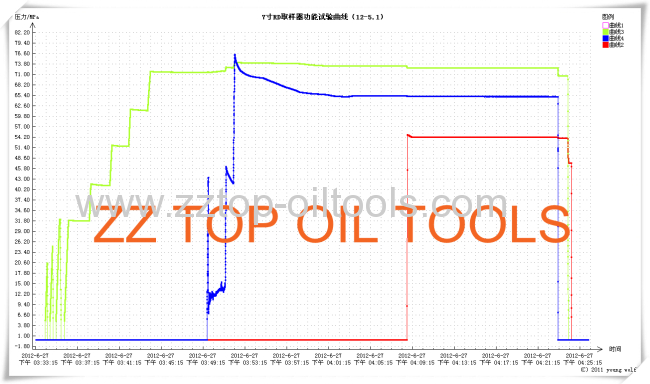

Pressure test chart

Function test

ZZ TOP OIL TOOLS is the professional manufacturer for the drill stem testing tools and surface testing equipment. All the DST tools are conformed with NACE MR 0175 with traceability,and the DST tools can be worked in H2S & CO2 above 175 F and full H2S, also with the skilled and experienced engineers, we can design the drill stem testing tools as per customer's well condition. Moreover, we supply the training in our factory and operation instruction at the well site. The DST tools are exported to USA, Colombia, India, Pakistan, Iran, Brazil etc. and enjoy the good reputation from the customers.

To shorten the delivery time, we proceeded the DST Tools in stock:

Packer,circualting valve,select tester valve,APR N-valve,OMNI valve,Hydraulic Jar,Tubing string tester

1. Full bore Packer, 7" Casing, working pressure 70Mpa, Working Temperature 400F, Connection: IF, 4set

2. Tester valve, 5", Working pressure 105Mpa, Working temperature 400F, Connection CAS. BXP, 4 sets

3. Hydraulic Jar,5", Working pressure 105Mpa, Working temperature 400F, Connection CAS. BXP, 4sets

4. Rupture disk Circulating valve, 5", Working pressure 105Mpa, Working temperature 400F, Connection CAS. BXP, 4sets

5. Flowhead (surface test tree), 3 1/16", working pressure 70 Mpa. 1set

Should you have any interest or inquiry on the Drill stem testing tools, contact us freely.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

.jpg)